Tips From

Frank the Tank

CORROSION PROTECTION

|

Tips From Frank the Tank |

|

|

|

CORROSION PROTECTION |

||

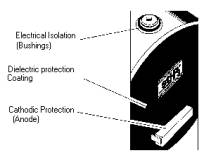

Tanks

made from non-corrodible materials such as fiberglass reinforced plastic (FRP)

or other non-corrodible materials do not require operation and maintenance for

corrosion protection. However, tanks and piping made from metal that

routinely contain regulated substances and are in direct contact with the ground

need corrosion protection and the corrosion protection requires proper operation

and maintenance.

Sacrificial

Anode Cathodic Protection Systems

Sacrificial

anodes are buried and attached to tank components for corrosion protection.

Anodes are pieces of metal that are more electrically active than steel, and

thus they suffer the destructive effects of corrosion rather than the steel they

are attached to.

Operation and Maintenance of

Sacrificial Anode Systems

You

need to have a periodic test conducted by a qualified corrosion tester to make

sure your cathodic protection system is adequately protecting your UST system.

This test needs to be conducted:

|

ü

|

Within

6 months of installation. |

|

ü

|

At

least every 3 years after the previous test. |

|

ü

|

Within

6 months after any repairs to your UST system. |

|

ü

|

Make sure that the professional tester is qualified to perform the test and follows a standard code of practice to determine that test criteria are adequate. |

|

ü

|

§

If

any test indicates that your tanks are not adequately

protected, you need to have a corrosion expert examine and fix your

system. §

Testing

more frequently can catch problems before they become big problems. |

|

ü

|

You

need to keep the results of at least the last two tests on file.

|